Genuine Rondels

The glazing of windows with round disks of glass called Rondels was widely used in the town houses of bourgeois families and other secular buildings during the Middle Ages. Today you can find Rondels incorporated into the windows of buildings in many old cities and in sensitively restored edifices.

The glazing of windows with round disks of glass called Rondels was widely used in the town houses of bourgeois families and other secular buildings during the Middle Ages. Today you can find Rondels incorporated into the windows of buildings in many old cities and in sensitively restored edifices.

Genuine Rondels are produced one at a time, by Glashütte Lamberts in the traditional method of blowing glass by mouth. This gives every Rondel a breath of life and brilliance that brings quality and makes every piece a unique work. That is what clearly distinguishes a blown Rondel from the “imitation” Rondel produced by means of pressing or spinning.

After reheating, it is cut open by means of a pair of special scissors. In order to be able to handle the glass more easily and to achieve a better stability the master turns down the rim through a special technique. As the master continually rotates the punty rod a small round Rondel takes shape. After reaching the final size the Rondel is tapped off the punty rod and slowly cooled in an oven.

Production

The molten glass is taken from the oven by means of the blowpipe. The quantity of glass is related to the desired finished size of the Rondel. It is then blown into to a small balloon the volume of which is second in importance as to the size. The creation of a uniform Rondel of high quality is finally dependent on the master’s craftsmanship and know-how. Still hot, the small balloon of glass is now stuck onto a punty rod and knocked off the blowpipe.

Nach erneutem Einwärmen wird diese mit der Auftreibschere geöffnet. Durch eine spezielle Technik schlägt der Butzenmacher den Rand um, so wird eine bessere Stabilität und Verarbeitbarkeit erreicht. In einer rotierenden Drehbewegung wird dann eine kleine, runde Butzenscheibe geformt. Nach Erreichen der endgültigen Größe wird sie abgeschlagen und im Kühlofen langsam abgekühlt.

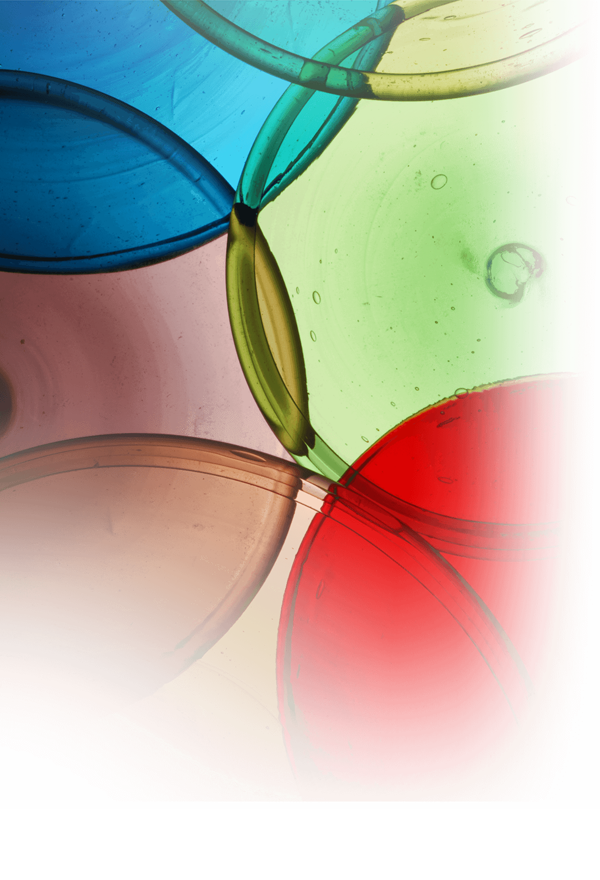

Technique and Colours

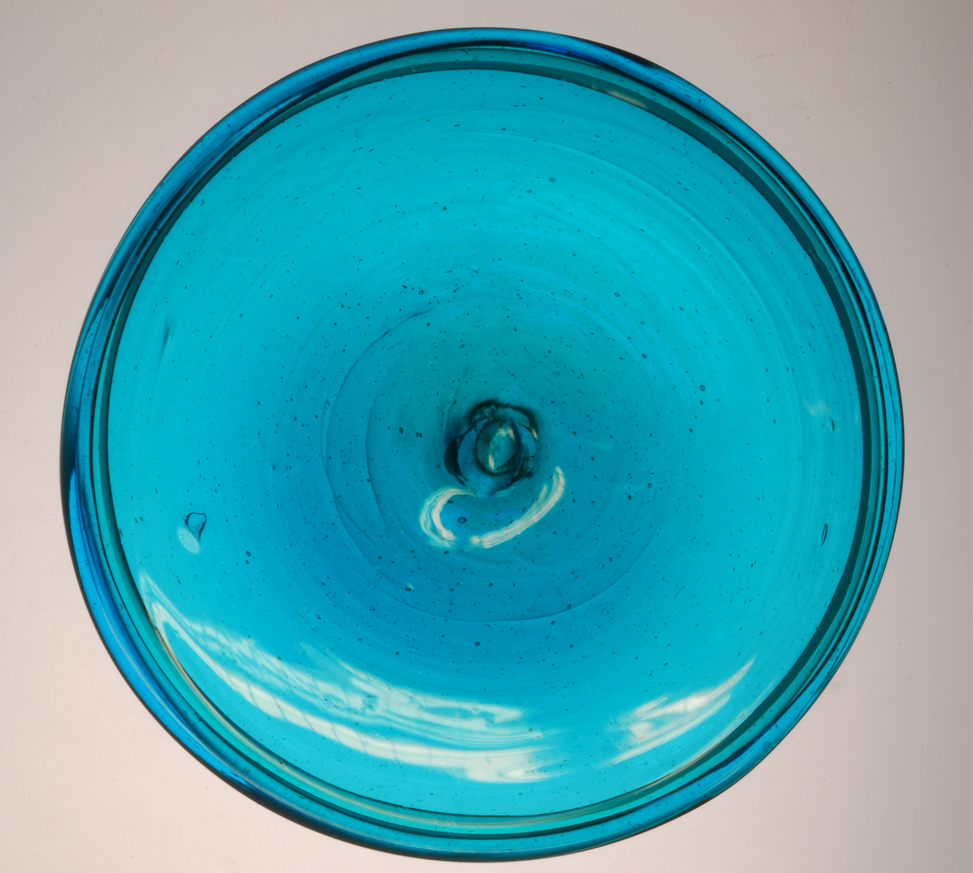

Genuine Rondels are produced in sizes of 6 to 13 cm in diameter. Deviations of +/- 0,4 cm occur because they are individually handcrafted. The thickness varies within the disk. The navel in the centre – sometimes sharpedged – and its adjacent area have a thickness of approx. 5 mm. The rest of the disk is approx. 2 to 3 mm in thickness. According to tradition the Rondels are produced in clear and bright colours. A special production for a colour and/or size is possible by special request.

Fields of application

There is in fact no alternative of equal value to Genuine Rondels when it comes to accurately restoring old windows adorned with such disks of glass. Many also prefer to glaze new windows with these Rondels. Individual Rondels incorporated into doors prove to be eye-catching and can be applied to lamps as well.