The Fascinating History of Glassmaking

Glass is a material that has fascinated and accompanied mankind for thousands of years. It is a material that plays a central role in art as well as in science, in everyday life and in industry. In this article we will dive deep into the history of glass making, from the first obsidian tools of the Stone Age to the technologies of today. We will also highlight the special techniques and features of the Lamberts Glassworks, one of the last manufactories in the world for hand-blown flat glass.

The beginnings: from obsidian to glass

The history of glass begins well before the invention of glass as we know it today. In the Stone Age, people were already using natural forms of glass such as obsidian, a volcanic glass stone, to make tools and weapons. Obsidian was a sought-after material because of its sharp edges and was prized in many cultures.

The first man-made glass objects date back to around 3500 BC and were found in the Near East. These early glass objects were mostly pieces of jewelry or small vessels. They were made by melting quartz sand in simple clay kilns. The color of the glass was influenced by the addition of natural minerals such as iron or copper oxides.

In the second millennium BC, glass production developed independently in different parts of the world. In Egypt, for example, colorful glass objects were made by adding metal oxides during the melting process. These Egyptian glass objects were so ornate that they were even used as burial objects for pharaohs.

The Romans and the glassmaker pipe

The Romans played a crucial role in the history of glass production. They were the first to produce and export glass on a large scale. One of the most important technical revolutions in the history of glassmaking was the invention of the glassmaker's pipe around 200 BC in Syria. This invention made it possible to create more complex shapes and improve the quality of the glass.

The glassmaker's pipe consisted of a long, hollow tube with a small amount of molten glass held at one end. By blowing air into the tube, the glass could be formed into various shapes. This technique revolutionized glassmaking and allowed the production of thin-walled, colorful glass vessels that were exported far beyond the borders of the Roman Empire.

The Romans also improved the kilns used to make glass. These furnaces were more efficient and reached higher temperatures, which improved the quality of the glass produced. The Romans were also the first to produce clear glass windows, a luxury previously unknown.

Middle Ages and Renaissance

During the Middle Ages, glassmaking was mainly concentrated in Venice, where the famous Murano glassblowers perfected their art. Murano glass was prized for its high quality and ornate designs. However, the quality of the glass was often inconsistent, and the techniques were closely guarded secrets. Glassblowers who left the island of Murano even risked the death penalty to keep the secret of Venetian glassmaking.

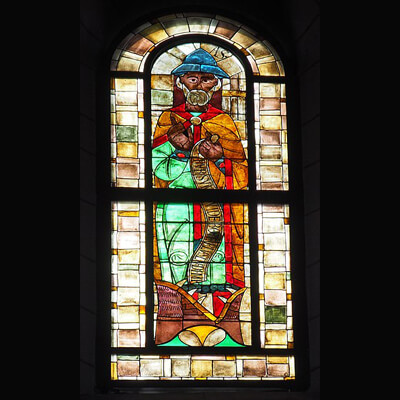

In the Middle Ages, the art of glassmaking reached a peak with the production of colored windows for churches and cathedrals. These windows were not only beautiful to look at, but also had deep symbolic meaning. The colors and images told stories from the Bible or the lives of saints and served as teaching tools for the faithful.

The production of colored glass was a complex process that required the addition of various metal oxides during the melting process. For example, cobalt oxide gave the glass a blue tint, while copper oxide colored it green.

During the Renaissance, scientists and artists began to explore the chemistry and physics of glass. Antonio Neri, an Italian alchemist, published the first book on glassmaking, "L'Arte Vetraria," in 1612. This book revealed many of the secrets of glass making and led to improved manufacturing methods. It was also the time when the first telescopes and microscopes were made, which emphasized the importance of clear and high quality glass. In 1679, Johannes Kunckel published his book "Ars Vitraria Experimentalis, oder Vollkommene Glasmacherkunst" (The Experimental Glassmaking Art, or Perfect Glassmaking Art), describing the almost complete knowledge of glassmaking available at the time.

The industrial revolution and modern technologies

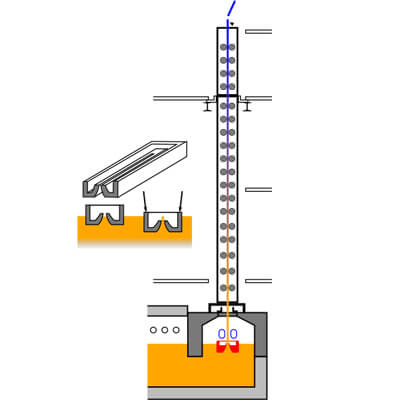

The Industrial Revolution brought massive changes to glass manufacturing. New inventions and technologies enabled the mass production of glass, which could now be used in a wide range of applications, from windows to bottles and from optical lenses to works of art. In the 20th century, machine processes such as the Fourcault process and the Libby-Owens process were developed.

These methods revolutionized the glass industry and made glass an affordable and widely used material. The Fourcault process, first introduced in Belgium in 1913, and the Libby-Owens process, developed in the United States, enabled the economical production of thin flat glass. These technologies led to an explosion in glass production and made glass an indispensable material in the modern world.

Glashütte Lamberts: tradition meets modernity

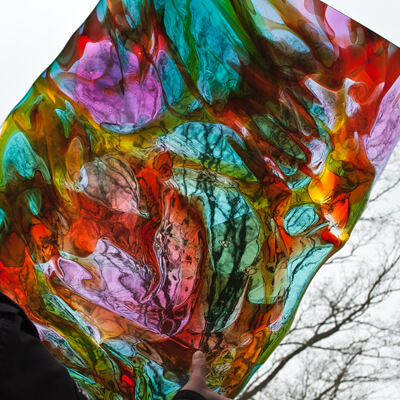

At a time when machine-made glass is the norm, Glashütte Lamberts holds fast to the traditional art of hand-blown flat glass. Founded in 1906, we are one of two remaining flat glass manufactories in the world. With a team of experienced glassmakers and state-of-the-art technologies, we produce glass of the highest quality that is used worldwide for architecture, restoration and historic preservation.

Our manufactory attaches great importance to sustainability and uses only natural raw materials. Each pane of glass is unique and bears the signature of the glassmaker. The Lamberts Glassworks is particularly well known for its hand-blown flat glasses, which are available in a variety of colors and textures. These glasses are used not only in historic buildings and monuments, but also in modern architectural projects that seek a blend of tradition, craftsmanship and elegance. Production using the traditional mouth-blowing process gives the glass a vibrant and characterful feel that is lacking in industrially manufactured products such as expressionless float glass.

State of the art

The history of glassmaking is a fascinating chapter of human creativity and innovation. From the first experiments with molten sand to the sophisticated technologies of today, this versatile material has had a long and eventful journey. And this journey is far from over. With advances in materials science and the growing demands for sustainable production, we are on the verge of a new era in glass manufacturing.

Lamberts Glassworks stands for the preservation of this traditional art and shows that there is a place for craftsmanship excellence even in our modern world. By combining traditional techniques with modern kiln technology, the manufactory strives for the highest quality and sustainability. Their products are proof that the art of glassmaking has not only survived, but is capable of evolving and thriving.

If you want to learn more about the fascinating world of glassmaking, from its historical roots to its cutting-edge technologies, Glashütte Lamberts is the place for you. Explore our website or visit us on site in Waldsassen, Germany to learn more about our unique hand-blown flat glasses and their sustainable manufacturing methods. Discover the art and science of glassmaking and become part of a tradition that has lasted for thousands of years.

Sources:

- "The History of Glass", Corning Museum of Glass

- "Glassmaking", Glass International

- "Technologies of Glass", Scientific American

- „Die Geschichte der Glasherstellung“, Planet Wissen

- „Die Geschichte der Glasherstellung“, Baunetz Wissen