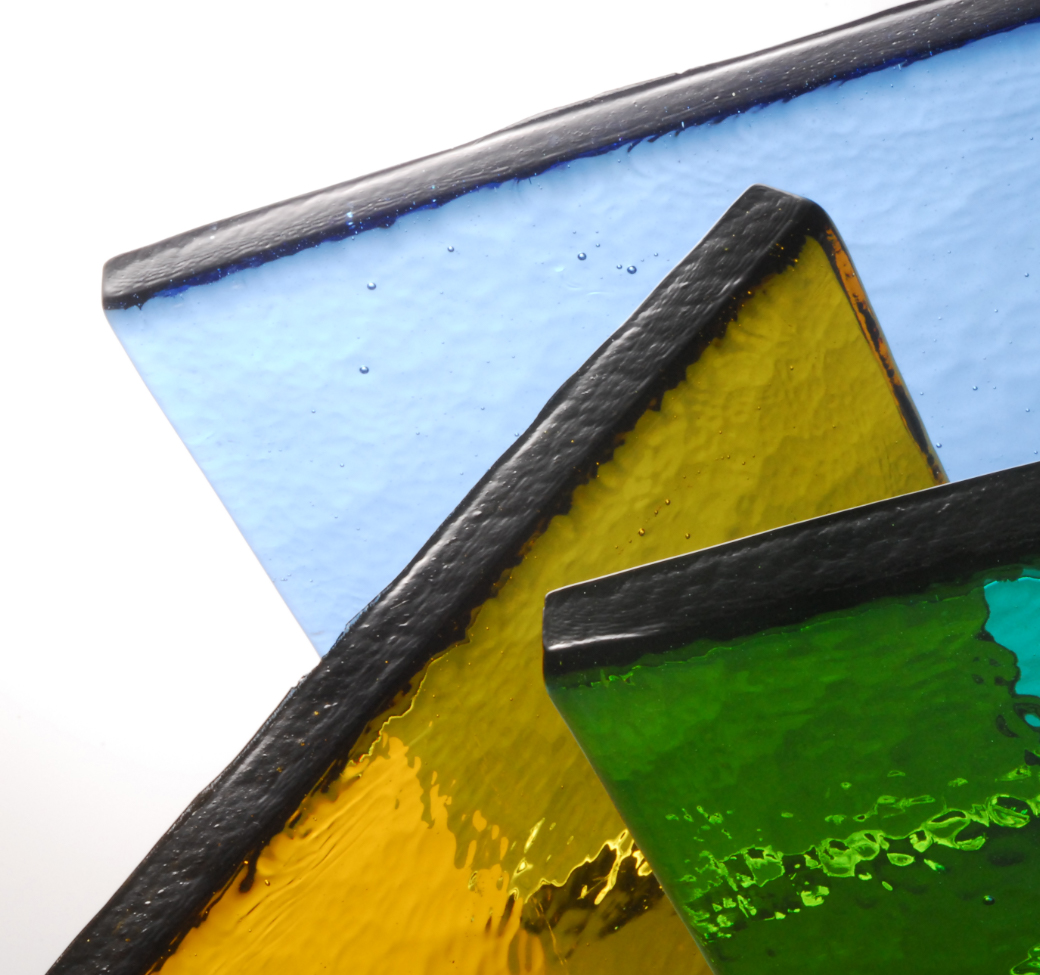

Dalle-Glasses - hand casted glass slabs - Dalle de verre

Dalle-Glasses are individually created by means of a hand casting procedure. Their surface is smooth with occasional open bubbles or streaks. The slabs have a standard size of 20x30 cm. and are approx. 24 mm thick. Due to the casting by hand the thickness can vary somewhat. Larger sizes are available by special order.

Dalle-Glasses are individually created by means of a hand casting procedure. Their surface is smooth with occasional open bubbles or streaks. The slabs have a standard size of 20x30 cm. and are approx. 24 mm thick. Due to the casting by hand the thickness can vary somewhat. Larger sizes are available by special order.

Glass slabs ( Dallen, Dalle de verre ) are melted in a variety of colors from glass batch and poured by hand into steel moulds.

Production

The moment the molten glass has been taken from the oven, it is cast into iron molds resting on top of thick slabs of graphite. After a short period of cooling the pieces are taken to an annealing oven where they slowly lose their tension.

Technique and colours

Traditionally, glass slabs are used for so-called concrete glazing. The Dalle de verre glass are processed (sawn, beaten or cut with a water jet) in such a way that the desired design parts are created. These parts are arranged on a table to form a design. The gaps are filled with special mortar for mechanical stabilization. After the mortar has hardened, the resulting elements are inserted into the window openings. This technique was used for the first time in the late 1920s.

The heyday of this technique was in the sixties and seventies of the last century.

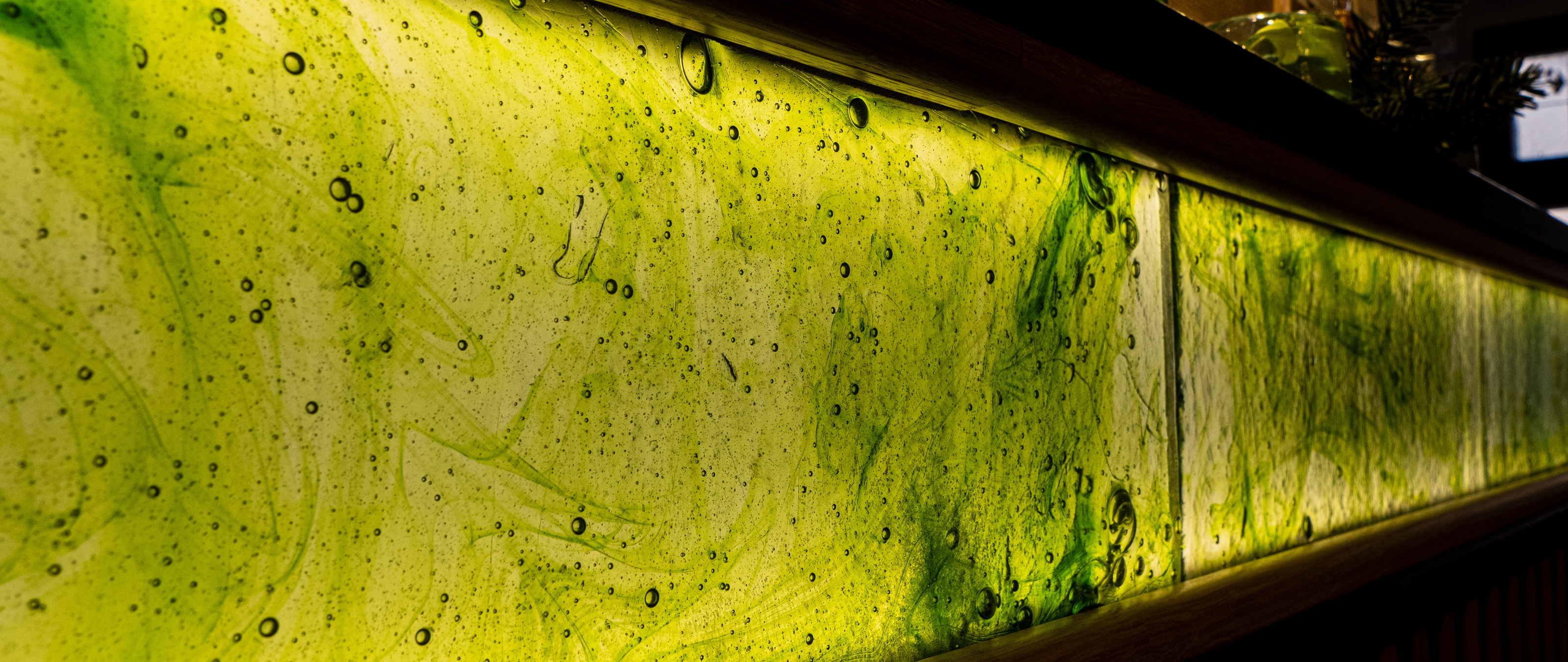

Completely new fields of application are currently emerging for cast glass.

It is now used in classic architecture, interior design and lighting design.

Fields of application

Dalle-Glasses are incorporated into fabricated concrete units, steel and wooden frames.