Plate discs

Tradition has it that the technique of glazing windows with mouth-blown „Plate Discs” was practised as early as in medieval times and was similar to that of producing and incorporating Rondel glasses.

Tradition has it that the technique of glazing windows with mouth-blown „Plate Discs” was practised as early as in medieval times and was similar to that of producing and incorporating Rondel glasses.

The „Plate Discs” were first made in the 12th and 13th centuries by glassworks located in the woods. The „Plate Discs” were initially used in castles, palaces and patrician houses. Then, during the Baroque period, mainly in sacred architecture.

Mostly produced in clear, „Plate Discs“ appear to be very simple, however their inner movement, a gentle spin, brings life into the window.

Production

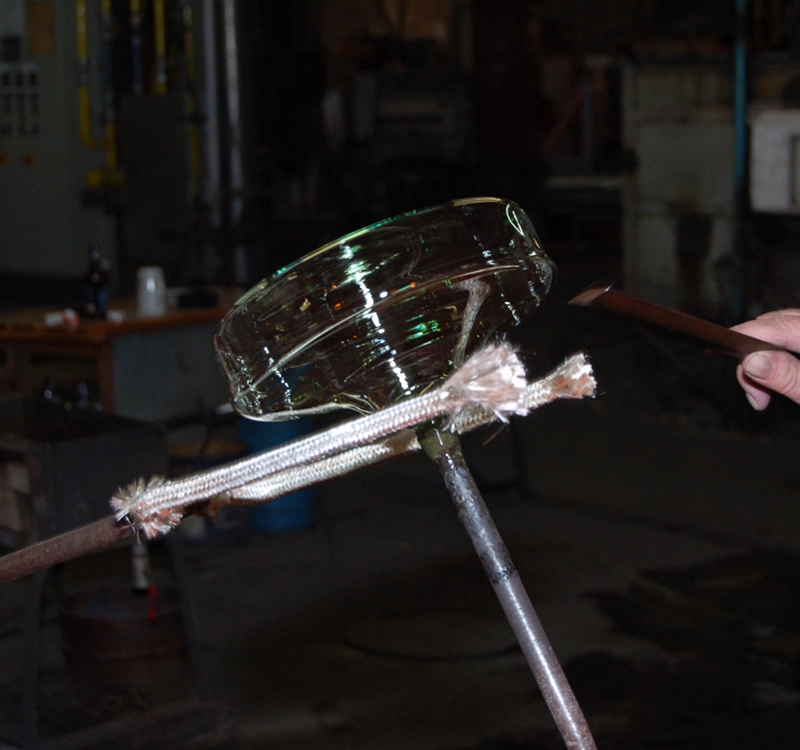

The molten glass is taken from the oven by means of the blowpipe. [01]

At first, the molten glass is given a spherical shape which, after being blown into a wooden mold, is spun into a comparatively flat, hollow body.

The piece is slowly cooled after the blowpipe has been knocked off.

By means of breaking off the upper part of the body, the bottom is left as a sort of “plate” from which the desired pieces such as round disks and hexagons can be cut.

Technique and colours

The handcrafted mouth-blown Plate Disks are used when it comes to accurately restoring or building new leaded windows. The „Plate Discs” produced purely by mouth-blowing are available in diameters ranging from 12 to 23 cm. Preference is given to clear and bright colours. The thickness varies from 2 to 3 mm.

Fields of application

Mouth-blown „Plate Discs” are used for accurately restoring or building new lead glazed windows.